THE MAGICIAN OF

Russ Gould

This article is about the discovery of something quite astonishing, all the more so because of the unlikely place it was discovered, and the absolutely stunning magnitude of the discovery.

Before we start with the account of this discovery, I would like to relate

another tale. There is a story about a hunting party in the

I made a similarly incongruous discovery on a recent visit

to a long-time Belgian friend and hunting partner now living in the South of

France, not far from

Out of this covered entry came Claude Bouchet, the gun-maker, to greet us. A compact man, he was wearing a powder blue shop coat and his eyes twinkled as we shook hands. Speaking very little French, I relied on my linguist friend to translate. We were duly invited into the kitchen and Claude then disappeared into the back of the house to fetch his gun. Looking around, I noticed stacks of gun magazines and books along the wall and a set of shotgun barrels hanging in a glass case on another wall.

He soon reappeared bearing what looked like a small gauge side-by-side shotgun with a side lever, profusely engraved. Upon closer inspection (I was warned not to touch the guns unless invited to do so), the gun now laid on a mat on the kitchen table was a double rifle. My friend explained that it was a 7x57. While we were looking at this very elegant and unique gun, Claude reappeared with yet another gun, somewhat larger. This one was a 300 Weatherby, we were informed. Also a full sidelock double rifle. It was laid next to the first. Another appeared…this time a very substantial over-under gun in 378 Weatherby. By this time I realized that there was a lot more to Claude than I had expected from a hobby gun-maker! A fourth gun was laid on the table, a massive double sidelever with an oversized action, announced as a 460 Weatherby! And finally, a gun that looked almost as big as Claude himself, a top lever side-by-side of massive proportions and obviously great weight. The caliber of this monster was 577 Tyrannosaur, a brutish wildcat cartridge clearly capable of slaying its namesake.

|

|

Claude with Massive 577 Tyrannosaur Double Rifle Made Entirely by His Own Hand, Employing his Unique Monolithic Barrels and Sidelever Action |

For a while I was at a loss for words. The guns were overwhelming, not only because of their size and power, but also due to their workmanship and styling. The most obvious common styling cue was that the receiver metal of each gun extended back to the narrow portion of the wrist. Each gun was a full hammerless sidelock, together with the extended actions providing acres of metal surface every inch of which was covered in deeply carved ornamental patterns with a menagerie of game animals done in Bulino-style engraving. It took a minute, but I then realized that there were no exposed pins in the action plates to detract from the engraving, only a H&H-style key on some or a hidden socket screw on others to hold the lock in place in its mortise in the action frame.

|

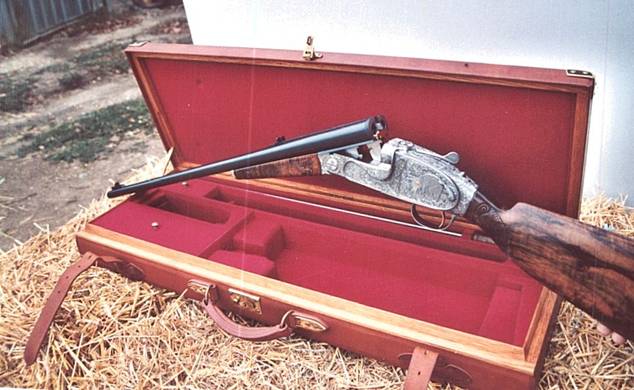

460 Weatherby SXS Rifle Showing Double Underlugs and Hidden Third Fastener, Keyed Hand Detachable Sidelocks in Extended Action Frame, in Maker’s Case |

|

The finely figured wood stocks, of best French Bastogne Walnut, met the actions at the transition from the wrist to what would normally be called the head of the stock…except that this portion of the gun was metal. Each stock was slightly different in design although none could be characterized as having classic proportions. The 7x57 and 300 Wby had perch-belly stocks with no pistol grip; the 378 and 577 had a pronounced pistol grip stock of stout proportions capped by an engraved metal cap; the 460 and 500 had a straight grip, but not of the English style. Each stock and forend was delicately carved with fish-scale patterns, leaves and fruit where normally simple checkering would be found. Claude pointed out that the junctions of the stocks and the receivers were rebated so the wood could not splinter, each stock being tapered and held tight to the receiver by a sturdy stock bolt. He further demonstrated that the forend wood was held in a “vise” of metal, and that the forend iron was one integral piece of metal with the hinge at one end and a cap at the other with dovetails to hold the wood in a firm grip. While removing a forend from one of the guns to demonstrate this design feature, he pointed out that the pushbutton release had to be first unlocked by unscrewing a knurled sleeve before the forend could be released.

|

|

|

|

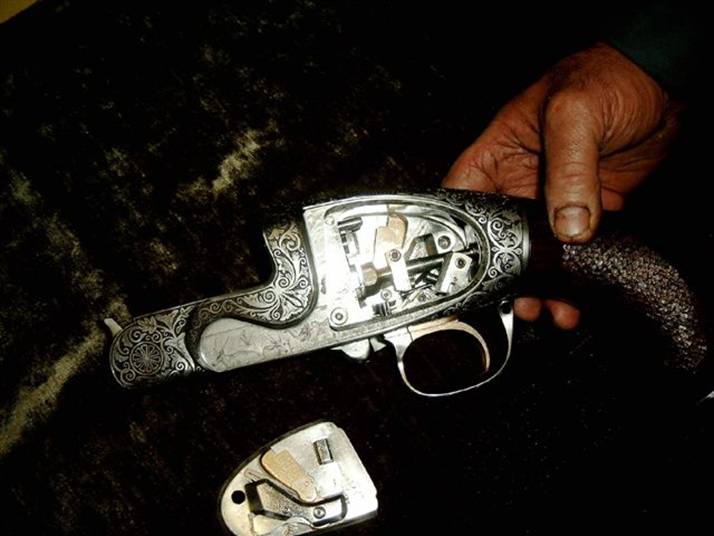

500 A-Square O/U Action with Linear Strikers. Note Polished Internals with Gold Plated Parts |

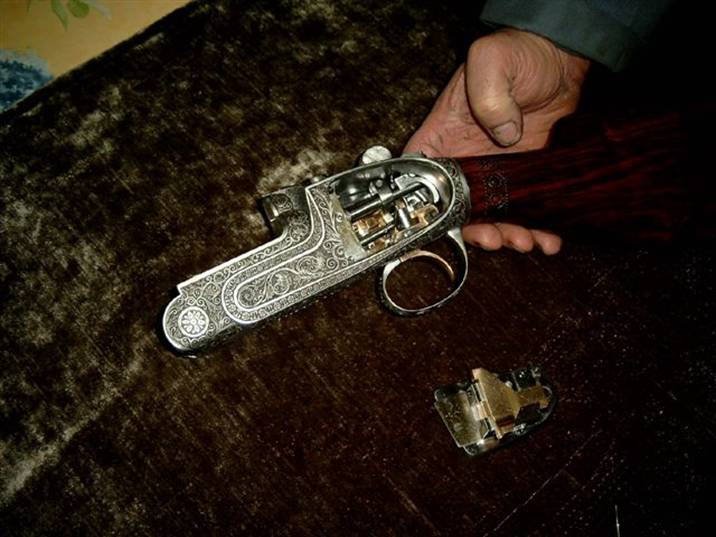

460 Weatherby SXS with Rotating Tumblers and Blocked Sears |

The lockwork was demonstrated

next. Each gun was provided with a means to remove the locks, either a hand

latch on the lock itself, or a special key stored in a hidden compartment

behind the buttplate. In a few seconds, the locks

were detached and their glorious mechanisms sparkled on the table like the

diamonds of the

Each gun had ejectors, according to its type. The

side-by-sides used H&H mechanisms in the forends,

while the

On most guns, even those made in by traditional hand methods, one is used to a little roughness in wood and metal finish in hidden areas such as the upper surface of the forend, the action mechanism, and the inside surfaces of the lockplates.

Not good enough for Claude though…his forend iron and the associated ejector mechanisms were polished to a mirror finish and the wood fit and finish on the interior surfaces was just as good as the exposed ones. Key pieces of his lockwork and ejectors were plated in gold. The fit and finish on the internal mechanisms of these guns is impeccable, bringing to mind the workings of a fine Swiss watch with the feel and heft of a bank vault door.

Regarding the exterior finish, we were amazed to note that with the exception of the first gun built (the 300 Wby), Claude had personally executed the engraving including the Bulino game scenes. Each gun bore appropriate renditions of game animals…from the “little” 7x57R with its depictions of local wild boar, mouflon, and roe deer to the lions and elephant on the 378, with the heavy artillery adorned with buffalo and rhino. The 577 exhibited a complete tableau with elephants and antelope on the left and a pride of lions on the right. The ornamental scroll and leaf work was deeply chiseled, offsetting the very fine game scenes. When we asked Claude how long it took him to perfect his technique, he shrugged and stated that he just started in on gun no. 2 and didn’t find it necessary to practice at all!

|

|

|

|

7x57 Sidelever Rifle with Mouflon on the Rump of the Action |

Same Rifle, Right Side Depiction of Boar’s Head |

|

|

|

|

300 Weatherby Rifle, Right Side Depiction of Wild Boar Common to Local Area |

Weatherby Again, Left Side

Showing Stag Against |

The biggest surprise was yet to come. The barrels of each

gun were as finely struck, polished and blued as any

|

|

|

|

Massive Integral Underlugs and Extractor on 577 Tyrannosaur. |

Business End of the 460 Wby Barrels Showing Integral Web |

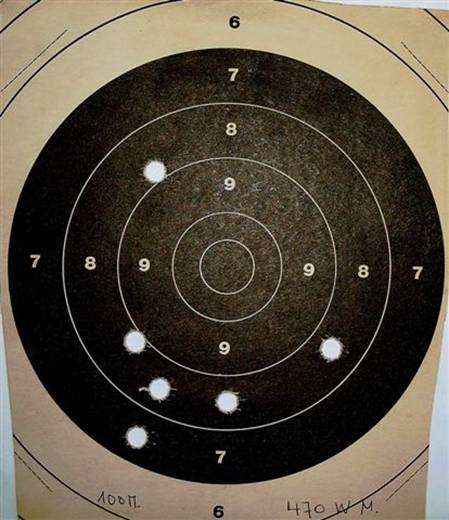

A lively discussion regarding regulation ensued. Claude stated that 80% of the regulation was accomplished by a slight convergence of the bores as drilled; with the final 20% being accomplished by cold-hammering the web between the bores “very carefully”. To prove his point, Claude dug through his pile of gun magazines and pulled out a carefully-preserved file of targets. In the case of the 300 Weatherby, he had a diagram showing two shots from either barrel before final regulation and finishing, fired from the barrels locked in a vise using a hammer. The pairs were tight to each other, less two inches apart, but the two pairs were separated on the diagram by about 8 inches. After regulation, a target reflecting about a dozen shots taken at 100 meters with the express sights did not show any distinct grouping for each barrel, the shots all lying within a grouping of 5 inches on the target. He then produced final groupings for each rifle, some regulated at 120 meters, others at 80 meters. As before, all bullets appeared to have come from one barrel and were centered in the bullseye. One could argue that some of the groups were a little broad, for example the 500 A Square group of 8 shots measured 4” by 6” at 120 meters (almost 150 yards), but Claude dismissed such talk by stating that the guns were fired with open express sights and that the vital area on their intended quarry was rather larger than the groups at 120 meters, and huge in comparison at 20 to 50 meters.

|

|

|

|

577 T Rex at 80 Meters (89 Yards) |

460 Weatherby at 100 Meters (120 Yards). |

When asked if he had killed anything with his guns, Claude

replied that he had not, and he had no plans to do so. He built the guns for

personal satisfaction, he stated, and not as everyday hunting weapons. He

wanted to advance the state of the art, to build the strongest and most

powerful guns extant, and to build them to the highest standards of

craftsmanship and finish. Each gun had taken three to four years to build,

working part time and late into the evenings mostly; laid out on the simple

kitchen table in front of us was a lifetime of work, literally!. We asked which guns he most enjoyed building, to which he

replied the “Boss” system gun, the 500. The forend

mechanism in particular proved most challenging. If he built another gun, was

there anything he would still like to improve? After some pause, the answer was

no, he felt he had proven every innovation he could think of and had built guns

that would sustain many thousands of rounds of heavy loads without complaint,

and then IF any wear occurred, he had incorporated wear-compensating blocks at

all wear points so the guns could be tuned up and made ready for the next bout

of use. Having had the wonderful opportunity to handle them (and yes, he did

allow me to do so with the gloves I brought along for the purpose), and having

seen how and where the guns were made, I found his statements bold but I could

find no argument with “The Magician of the

Postscript: Claude has committed to build one more gun, a prototype of a 12 lb working gun in a caliber suitable for use on dangerous game, specifically designed to be the toughest and most durable double rifle ever made, incorporating his many innovations and ideas with a few twists and surprises that won’t be revealed until the work is done. If all goes well, this gun will be produced in limited quantities with bespoke engraving and stocks, with deliveries starting in 2010.

Table Summarizing the Key Design Features of the Guns

|

Caliber |

Action |

Ejectors |

Bbl length |

“Rib” |

Sights |

Strikers |

Weight |

|

7x57R (275 Rigby) |

Side Lever SXS |

H&H |

|

Half |

Fixed Express and Scope Base |

Rotary |

4.5kg |

|

300 Wby |

Top Lever SXS |

H&H |

|

Half |

Fixed Express and Scope Base |

Rotary |

5.5kg |

|

378 Wby |

O/U Kersten Locks |

|

|

Full |

Fixed Express |

Linear |

7.5kg |

|

460 Wby |

Top Lever SXS |

H&H |

67cm |

Full |

Fixed Express |

Rotary |

9kg |

|

500 A-Square |

O/U Boss System |

Boss |

70cm |

Full |

Fixed Express |

Linear |

8.5kg |

|

577 Tyrannosaur |

SXS Side Lever |

None |

60cm |

Full |

Fixed Express |

Rotary |

10.5kg |